The Mollar CGT20750 drawing refers to the technical schematics or blueprints associated with the Mollar CGT20750 model, a device or system known for its precision in mechanical and electrical engineering fields. As of 2024, understanding the Mollar CGT20750 drawing has become essential for engineers, designers, and manufacturers, as it provides vital insights into the assembly, functionality, and optimization of the device. This article will delve into what the Mollar CGT20750 drawing is, its components, and its significance in current industrial practices.

Understanding the Mollar CGT20750 Drawing

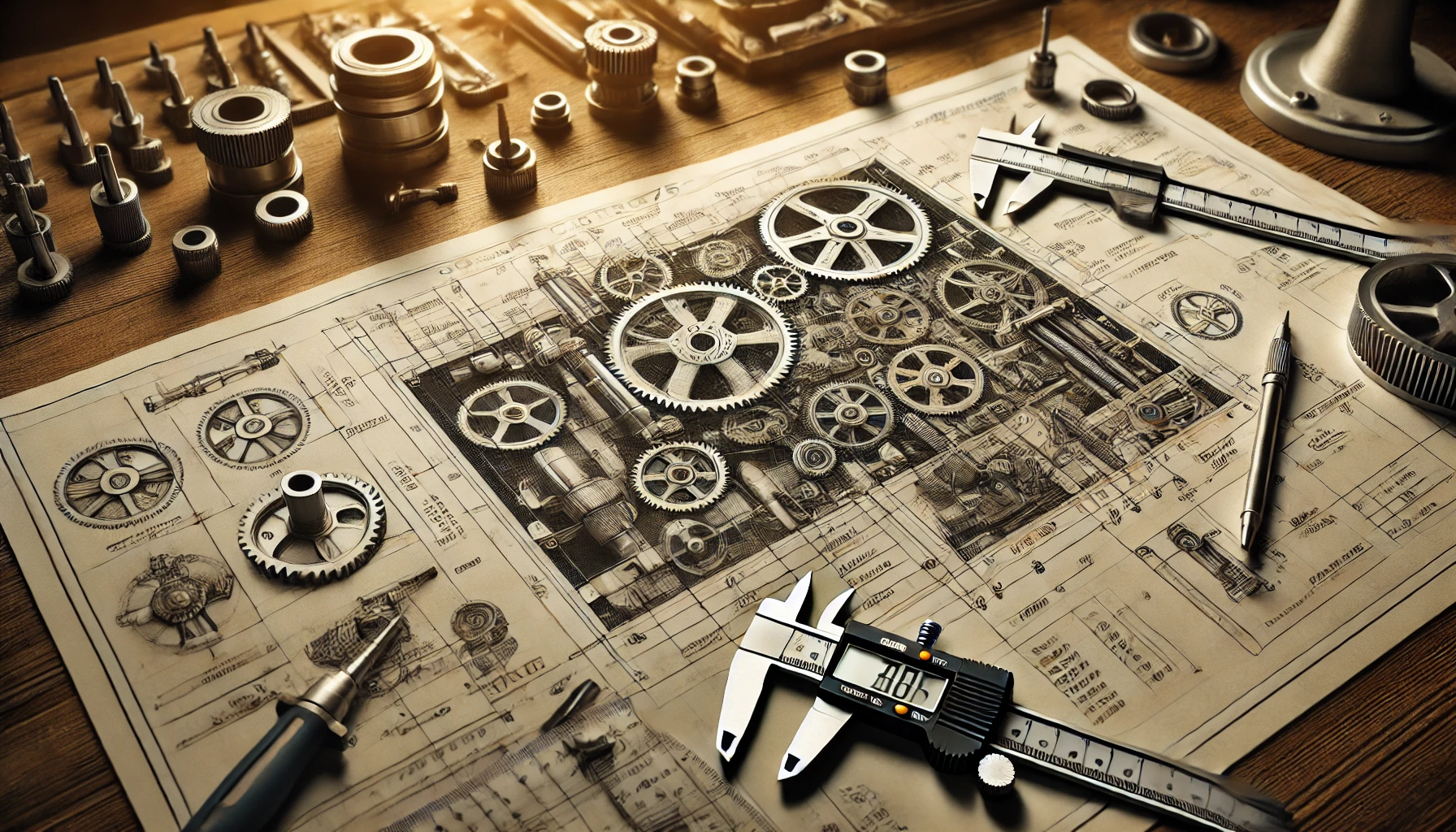

The Mollar CGT20750 drawing serves as a detailed visual representation that outlines the intricate design of the device. This drawing is critical for anyone involved in the production, maintenance, or modification of the CGT20750. It provides key information such as dimensions, specifications, part placements, and wiring diagrams that are essential for ensuring accuracy in both the construction and function of the device.

In 2024, as technology advances, precise engineering drawings like the Mollar CGT20750 are more important than ever. The demand for high-quality, efficient systems means that even the slightest deviation in the production process could lead to significant operational issues. The technical drawing ensures that every part is produced and assembled according to strict guidelines, reducing errors and improving performance.

Key Components of the Mollar CGT20750 Drawing

To fully understand the Mollar CGT20750 drawing, it’s important to break down its essential components. Each aspect of the drawing serves a specific purpose in the overall design and functionality of the device. Here are the key components typically found in this type of technical drawing:

- Dimensions and Tolerances:

The drawing includes precise measurements for each part of the CGT20750, along with tolerances that indicate acceptable deviations in size. These dimensions are critical for ensuring parts fit together properly and operate as intended. - Parts List (Bill of Materials):

The drawing features a comprehensive list of all parts and materials required for assembly. This helps manufacturers procure the right components and ensures that nothing is overlooked during production. - Sectional Views:

Sectional views are included to show the internal structure of the CGT20750, giving a clearer understanding of how the internal components are arranged and how they interact with one another. - Wiring and Circuit Diagrams:

Electrical systems are an integral part of the CGT20750, and the drawing often includes detailed wiring diagrams. These diagrams help electricians and engineers properly connect the device’s electrical components to ensure smooth functionality. - Assembly Instructions:

Step-by-step instructions or guides for assembling the CGT20750 are often included in the drawing. These instructions ensure that the assembly process follows a precise sequence, reducing the chances of errors. - Material Specifications:

The drawing specifies the materials that should be used in different parts of the device, taking into account factors such as durability, strength, and conductivity, depending on the part’s function.

Applications of the Mollar CGT20750 Drawing in 2024

The Mollar CGT20750 drawing has a wide range of applications in 2024, especially in industries where precision is paramount. Here are some of the key areas where these drawings are utilized:

1. Manufacturing:

In manufacturing, these technical drawings are essential for guiding the production process. Whether it’s the machining of parts or the assembly of components, the Mollar CGT20750 drawing ensures that every part is made to exact specifications, reducing defects and enhancing overall product quality.

2. Maintenance and Repairs:

When repairs are needed, technicians rely on the technical drawings to understand the device’s layout. The detailed schematics allow them to quickly identify which parts need replacement and how to access internal components without damaging the device.

3. Product Development:

Engineers and designers use the Mollar CGT20750 drawing during the product development phase to visualize the final product. The drawings are often used for simulations and tests to ensure that the design is functional before it moves into production.

4. Training and Documentation:

Companies that manufacture or work with the CGT20750 model use the drawings for training purposes. They provide a comprehensive guide for engineers and technicians, helping them familiarize themselves with the device’s structure and functionality.

Why the Mollar CGT20750 Drawing is Critical for Success

In 2024, precision engineering has reached new heights, and the Mollar CGT20750 drawing plays a pivotal role in this progress. Here’s why these technical drawings are more critical than ever:

- Ensuring Accuracy:

Accurate drawings ensure that each part of the CGT20750 is manufactured to the correct dimensions, preventing costly errors in the production line. - Facilitating Communication:

These drawings serve as a universal language for engineers, designers, and technicians. They provide a clear and concise way to communicate complex information about the device, reducing the risk of misinterpretation. - Improving Efficiency:

By providing detailed assembly and maintenance instructions, the Mollar CGT20750 drawing helps streamline processes, allowing technicians to complete tasks more efficiently. - Reducing Costs:

Precise technical drawings reduce the risk of errors and rework in the manufacturing process, leading to cost savings. Additionally, they help prevent downtime by providing accurate information for repairs and maintenance.

Future Trends and Innovations

As we look toward the future, the role of technical drawings like the Mollar CGT20750 will only continue to grow in importance. With advancements in digital modeling and simulation technology, these drawings are becoming more interactive, allowing engineers to test designs in virtual environments before they are physically produced.

Additionally, industries are beginning to adopt AI-driven tools to automate the creation and analysis of technical drawings. This allows for even greater accuracy and efficiency in the design and manufacturing processes.

How to Utilize Mollar CGT20750 Drawings Effectively

If you’re working with the Mollar CGT20750 drawing, here are a few tips to ensure that you’re using the document effectively:

- Review the Entire Drawing:

Make sure to study the drawing in its entirety before starting any work. Understanding all components and their relationships will help you avoid mistakes during production or assembly. - Check for Updates:

In fast-paced industries, technical drawings can be updated frequently. Always ensure that you are working with the latest version to avoid discrepancies. - Collaborate with Your Team:

Communication is key when working with complex systems like the CGT20750. Make sure everyone involved in the project has a clear understanding of the drawing to ensure a smooth workflow.

Here is Our Latest Article: What is Поррозаб? A Comprehensive Guide in 2024