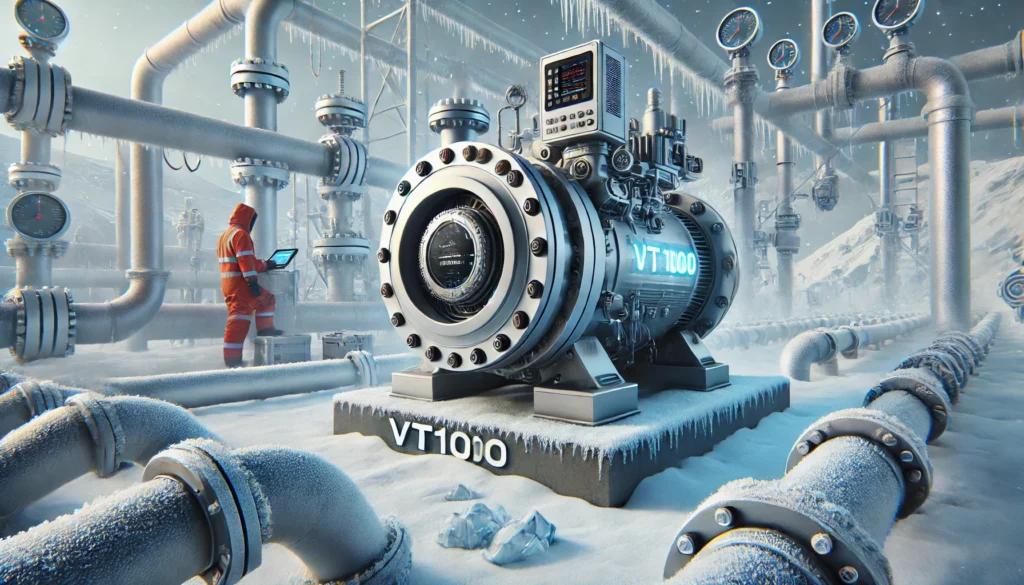

The VT1000 in subzero LNG environments represents a groundbreaking advancement in handling liquefied natural gas (LNG) under extreme conditions. As the LNG industry grows due to the global shift towards cleaner energy sources, technologies like the VT1000 are becoming indispensable for ensuring reliable and efficient operations in subzero temperatures. From LNG liquefaction to storage and transportation, the VT1000 excels in maintaining operational stability, reducing downtime, and optimizing energy consumption.

How VT1000 Operates in Subzero LNG Environments

The LNG industry relies on equipment that can withstand harsh conditions, such as the extreme cold needed to keep natural gas in its liquid form at approximately -162°C (-260°F). The VT1000’s design is tailored specifically for this challenge, offering unparalleled resilience in subzero environments. Equipped with thermal insulation, corrosion-resistant materials, and advanced monitoring systems, it ensures that critical operations continue smoothly, even as temperatures plummet below freezing.

Key Features of VT1000 in Subzero Conditions

- Temperature Resilience: The VT1000 can function effectively in temperatures as low as -200°C (-328°F), critical for maintaining LNG’s liquid state. This resilience helps prevent operational failures that are common in such extreme conditions.

- Pressure Management: Subzero LNG environments often involve high-pressure systems. The VT1000 is built to manage and monitor these pressures, ensuring safety and preventing potential equipment failures.

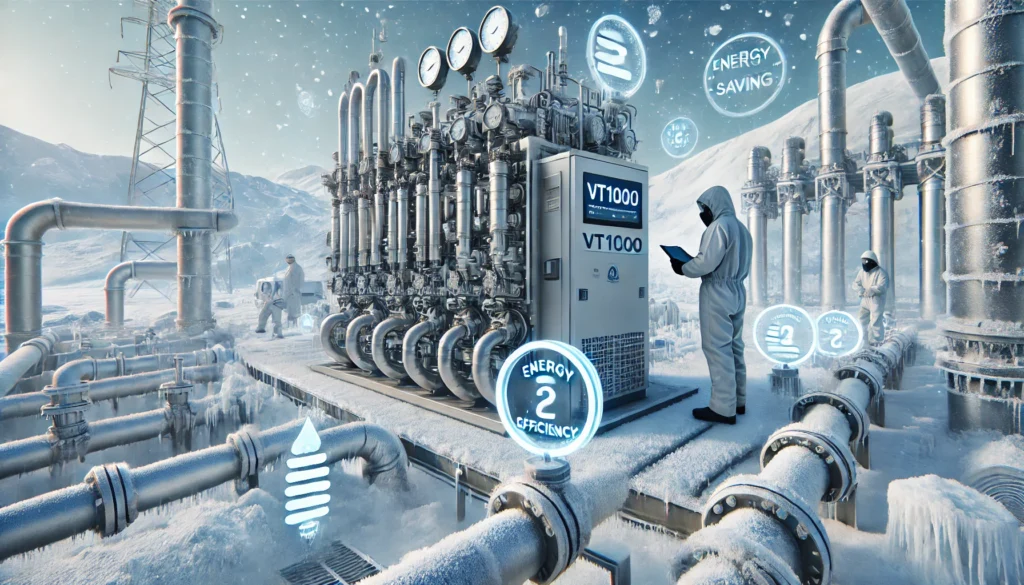

- Energy Efficiency: The VT1000 is designed to optimize energy use, which is essential for reducing operational costs in LNG plants where energy consumption is significant.

- Safety and Reliability: Advanced safety features such as real-time monitoring allow the VT1000 to detect and address potential risks before they escalate, ensuring safe operations in remote and hazardous LNG environments.

Applications of VT1000 in LNG Operations

The VT1000 plays a critical role across various stages of LNG operations:

- Liquefaction Plants: It ensures efficient cooling of natural gas into its liquid form, a vital process in the LNG supply chain.

- LNG Storage: Maintaining LNG in storage tanks at subzero temperatures is essential for its safe handling. The VT1000 helps in regulating and monitoring these temperatures, preventing the gas from reverting to its gaseous state.

- Transportation: The VT1000 ensures that LNG remains stable during long-distance transport, where maintaining a consistent temperature is critical to preventing losses.

Benefits of Using VT1000 in Subzero LNG Environments

- Reduced Downtime: Its robust design minimizes wear and tear, leading to fewer repairs and reduced downtime in LNG operations.

- Enhanced Safety: The VT1000’s safety features and real-time monitoring ensure the smooth and secure handling of LNG, preventing accidents and protecting both equipment and personnel.

- Cost Efficiency: By optimizing energy consumption and reducing the need for frequent maintenance, the VT1000 helps lower operational costs, making it a more cost-effective solution compared to conventional equipment.

Future of VT1000 in LNG Industry

The demand for reliable equipment like the VT1000 is expected to rise as the LNG industry expands, especially in regions with extreme climates. Future developments may include enhanced automation, further improvements in energy efficiency, and a continued focus on sustainability to minimize the environmental impact of LNG operations.

Conclusion

The VT1000 in subzero LNG environments is a critical innovation that enhances both the safety and efficiency of LNG operations. Its ability to operate under extreme cold, combined with its energy efficiency and durability, makes it an invaluable tool for LNG facilities worldwide. As the industry continues to grow, the VT1000 is set to play an even more significant role in ensuring the successful handling of liquefied natural gas in some of the harshest environments on Earth.

Here is My Latest Article: What is 3214387828? Understanding the Purpose Behind Calls from This Number